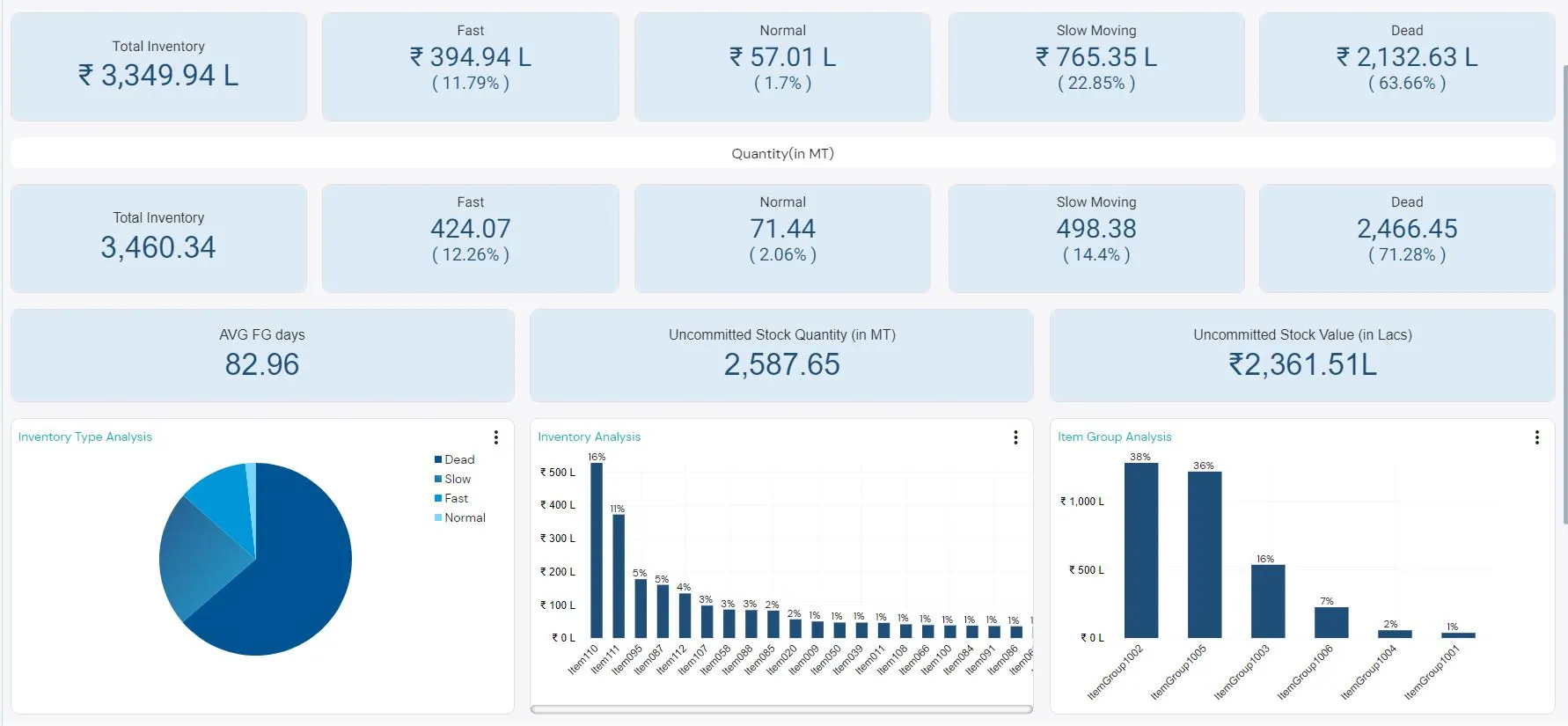

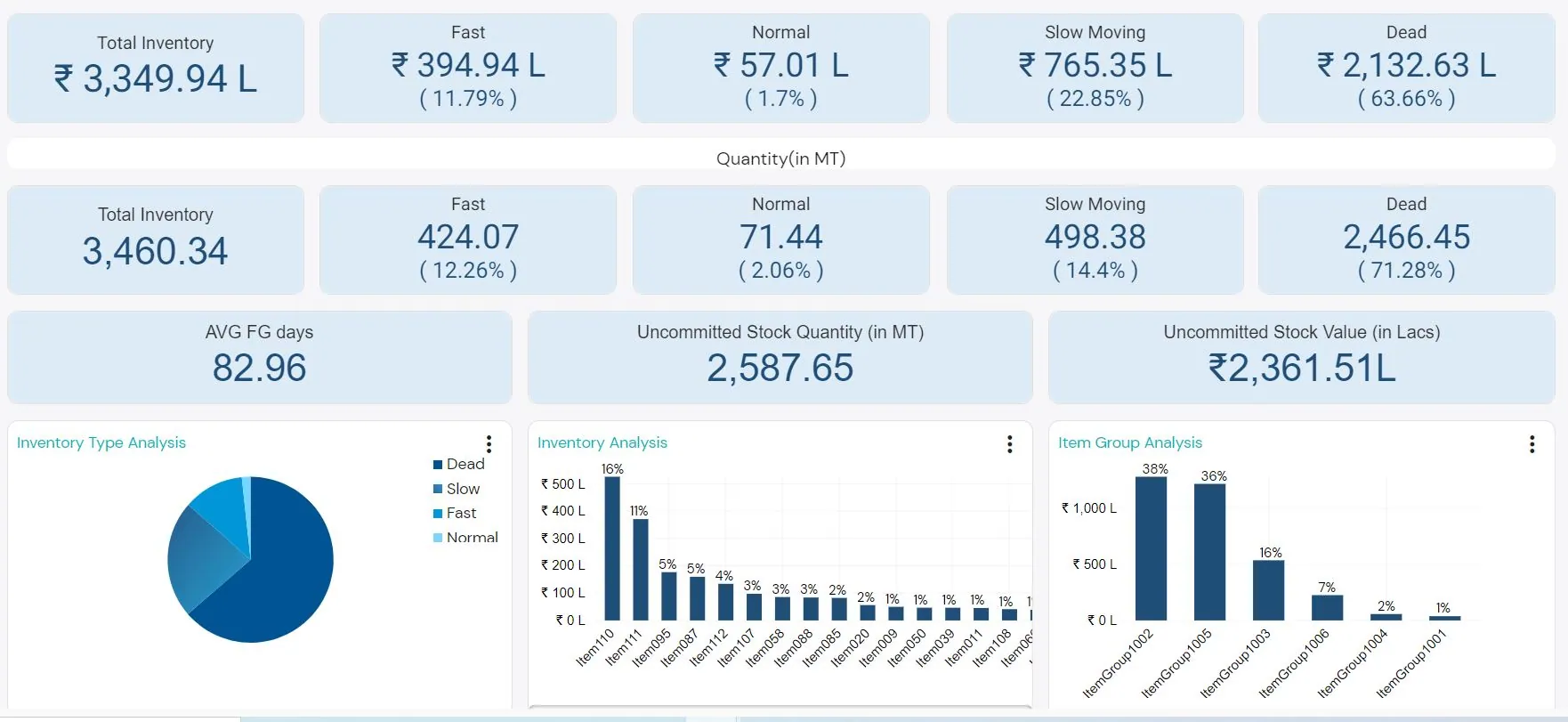

Optimizing inventory management with inventory data analytics

Our AI-based inventory analytics, built into our inventory management software, have been designed to optimize inventory levels, reduce costs, and improve overall operational efficiency. It includes analyzing key inventory metrics such as inventory turnover ratio, carrying costs, stockouts, and obsolescence. By leveraging inventory data analytics through your inventory management software, businesses can identify slow-moving or obsolete items, implement strategies for better demand forecasting, streamline reorder processes, and optimize warehouse space utilization. This analysis helps in maintaining adequate stock levels, avoiding excess inventory, improving cash flow, and enhancing customer satisfaction through timely order fulfillment. Inventory data analytics aids companies in making informed decisions to balance inventory investment while meeting customer demand effectively.