Enhancing production efficiency with product analytics dashboard software

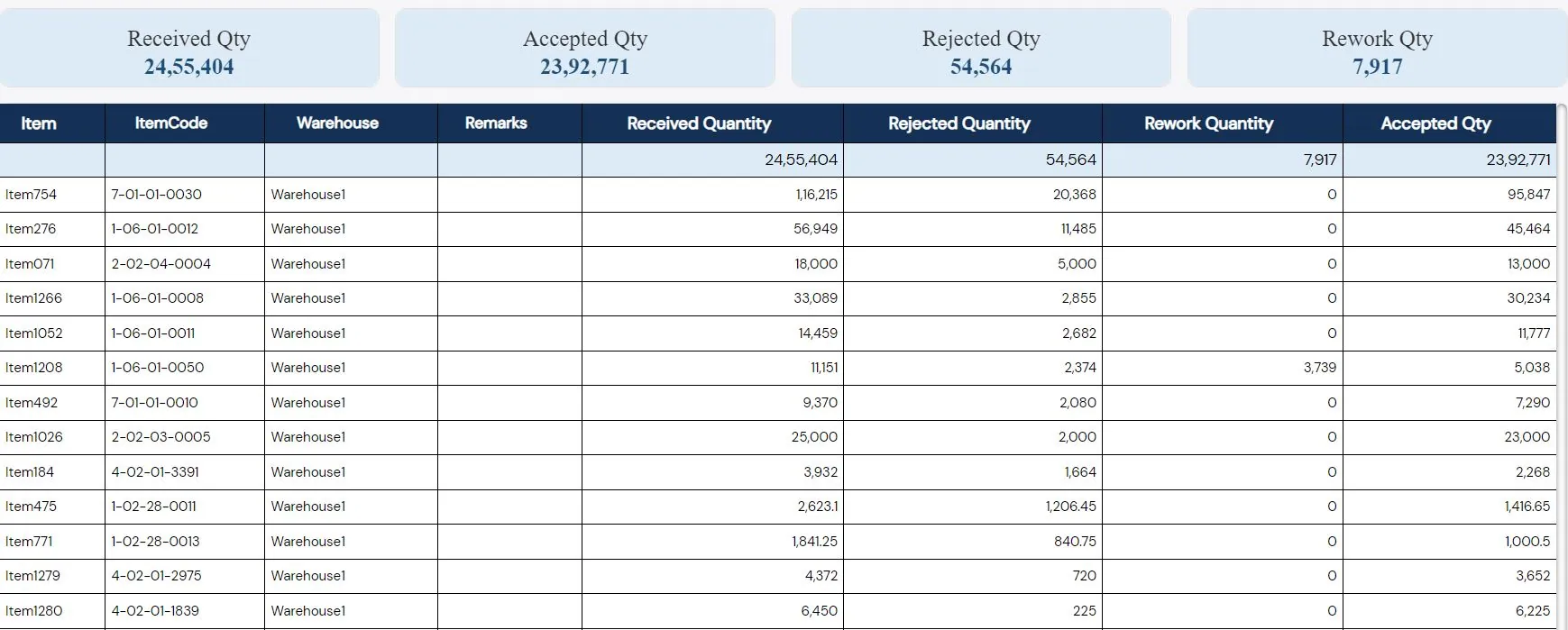

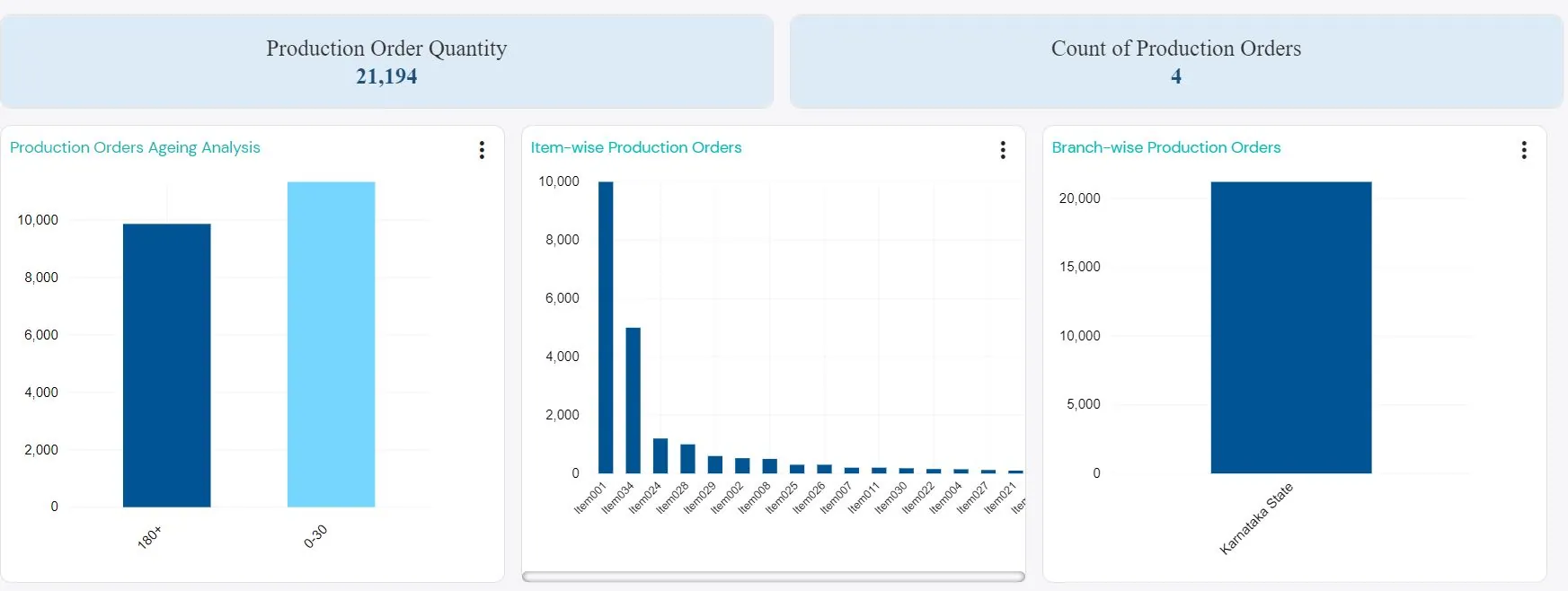

The Production Analytics Module involves assessing and evaluating the production processes and activities within an organization to improve efficiency, productivity, and overall performance. It includes analyzing key metrics such as production output, cycle time, utilization rates, and quality control measures. By leveraging product analytics dashboard software, businesses can gain deeper insights into their production processes, identify bottlenecks, streamline workflows, optimize resource allocation, and pinpoint areas for improvement. It helps in identifying production inefficiencies, reducing costs, improving product quality, and meeting customer demands effectively. Through the use of various tools and techniques, product analytics dashboard software enables organizations to enhance their production capabilities, increase profitability, and maintain a competitive edge in the market.